DIY:12U Rack: Difference between revisions

No edit summary |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 2: | Line 2: | ||

<div id="tocalign">__TOC__</div> | <div id="tocalign">__TOC__</div> | ||

{{Back|DIY}} | {{Back|DIY}} | ||

= {{Icon24|sitemap}} Introduction = | == {{Icon24|sitemap}} Introduction == | ||

In May of 2018 I built a 14U wooden rack frame, while working fine it was a very rudimentary build with no flair, heck not even rails (equipment was fastened directly to the wood). | In May of 2018 I built a 14U wooden rack frame, while working fine it was a very rudimentary build with no flair, heck not even rails (equipment was fastened directly to the wood). | ||

| Line 154: | Line 154: | ||

== {{icon|camera-lens}} Build Pictures == | == {{icon|camera-lens}} Build Pictures == | ||

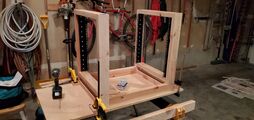

I attempted to document the process as best as I could. The frame was made from the 2x4s once they were transformed into 1.5x3s, the bottom mini-frame is supported by oak 2x1s that I cut from a piece of oak (1x5) in my scrap bin. I then wrapped the frame in 1/2" sanded plywood, using hardwood dowels to secure the rear frame (making it removable). | I attempted to document the process as best as I could. The frame was made from the 2x4s once they were transformed into 1.5x3s, the bottom mini-frame is supported by oak 2x1s that I cut from a piece of oak (1x5) in my scrap bin. I then wrapped the frame in 1/2" sanded plywood, using hardwood dowels to secure the rear frame (making it removable). | ||

<gallery caption="12U Rack Cabinet Build Pictures" widths=256px perrow=2 style="margin:0 auto;"> | |||

File:20201219_115036.jpg|01. Began by cutting all the frame pieces down to size. | |||

File:20201222_133216.jpg|02. With the frame pieces all cut to size it's time for sanding. | |||

File:20201223_141738.jpg|03. All pieces were sanded with 80, 120 and then 220 grit. | |||

File:20201225_003231.jpg|04. Pocket holes are then drilled in all required pieces. | |||

File:20201225_003500.jpg|05. All of the frame pieces receive three coats of lacquer. | |||

File:20201226_160521.jpg|06. The rack rails were then attached to the four posts. | |||

File:20201226_161847.jpg|07. All posts were subsequently labeled. | |||

File:20201226_163851.jpg|08. Frame assembly began, starting with the rear. | |||

File:20201226_172535.jpg|09. The front and rear were then connected to form the full frame. | |||

File:20201226_223510.jpg|10. Horizontal beams were added to support the weight of the battery backup units. | |||

File:20201228_144910.jpg|11. With the frame finished, all the plywood was then cut to size for the cabinet paneling. | |||

File:20201228_170003.jpg|12. Once the plywood was cut, they were sanded and given the lacquer treatment. | |||

File:20201229_142542.jpg|13. Cabinet assembly was pretty straight forward, I took a deviation from the plans here and decided to nail most of the panels together. | |||

File:20210101_124517.jpg|14. Using a hole saw, I cut two ports on the back compartment for wire grommets. | |||

File:20210101_124535.jpg|15. Using a combination jigsaw and then router I cutout a slot for a 2U vented blank that will function as an air intake. | |||

File:20210102_222313.jpg|16. Four hardwood dowels and four oak stop-blocks allow the back panel to be removable. | |||

File:20210103_111505.jpg|17. Test fit of the back panel looks good. | |||

File:20210104_135119.jpg|18. Casters were installed with lag screws. | |||

File:20210105_150254.jpg|19. After a day or two in the garage to let the glue/finish settle I lugged it inside. | |||

File:20210108_154058.jpg|20. Despite the front door not being finished I decided to swap the old rack for the new one, installing everything with Rackstuds. | |||

</gallery> | |||

[[Category:DIY]] | [[Category:DIY]] | ||

Latest revision as of 13:50, 7 February 2021

Introduction

Introduction

In May of 2018 I built a 14U wooden rack frame, while working fine it was a very rudimentary build with no flair, heck not even rails (equipment was fastened directly to the wood).

In the beginning of 2020 as nothing more than wishful thinking, I began designing a rack cabinet in SketchUp. Beginning as a 24U cabinet (2 revisions), shifting to a 20U cabinet (3 revisions), then 12U cabinet (3 revisions), then dual 12U desk (2 revisions) and finally settling back on 12U rack cabinet (4 more revisions). Based on the EIA/ECA-310-E specification, I started with the Z-Series rails from Star Case and included all the features I wanted in a cabinet.

Plans

Plans

Parts List

Parts List

Glass

Glass

- LEXAN 11" x 14" x 0.093" Clear Polycarbonate Sheet-GE-34

GE-34

GE-34 8.98 — Home Depot (Purchased: 2021/01/04)

8.98 — Home Depot (Purchased: 2021/01/04)

Lumber

Lumber

- 1" x 4" x 39" Common Board Bed Slat

1001749849

1001749849 2.39 — Home Depot (Purchased: 2020/12/31) |

2.39 — Home Depot (Purchased: 2020/12/31) |  3

3

- 2" x 4" x 92-5/8" Prime Whitewood Stud

569062

569062 4.98 — Home Depot (Purchased: 2020/12/14) |

4.98 — Home Depot (Purchased: 2020/12/14) |  6

6

- Endesa Sandeply Plywood 1/2" x 4' x 8' (12mm)

454532

454532 35.95 — Home Depot (Purchased: 2020/12/28)

35.95 — Home Depot (Purchased: 2020/12/28)

- Kelleher 3/8" x 48" Round Dowel

IM6406U-40

IM6406U-40 0.98 — Home Depot (Purchased: 2021/01/01)

0.98 — Home Depot (Purchased: 2021/01/01)

Hardware

Hardware

- Everbilt 5/16" x 2" Stainless Steel Hex Lag Screw, 5 pc.

812680

812680 7.56 — Home Depot (Purchased: 2020/12/31) |

7.56 — Home Depot (Purchased: 2020/12/31) |  2

2

- Everbilt Surface Mount Soft Close Hinge, 2 pc.

9289518

9289518 11.48 — Home Depot (Purchased: 2021/01/04)

11.48 — Home Depot (Purchased: 2021/01/04)

- Kreg 2-1/2" Coarse Zinc-Plated Steel Square-Head Pocket Screw, 50 pc.

SML-C250-50

SML-C250-50 5.97 — Home Depot (Purchased: 2020/11/09) |

5.97 — Home Depot (Purchased: 2020/11/09) |  2

2

- SPAX 5/16" x 3" POWERLAG Hex Drive Washer Head Lag Screw

4571820800757

4571820800757 0.87 — Home Depot (Purchased: 2020/12/31) |

0.87 — Home Depot (Purchased: 2020/12/31) |  4

4

- Teks #8 x 1" Philips Truss-Head Lath Screw, Zinc-Plated, 170 pc.

21508

21508 7.57 — Home Depot (Purchased: 2020/12/26)

7.57 — Home Depot (Purchased: 2020/12/26)

- TITAN Industrial 2" Polyurethane Swivel Caster w/ Brake

4126599LN

4126599LN 6.98 — Lowe's (Purchased: 2020/12/31) |

6.98 — Lowe's (Purchased: 2020/12/31) |  4

4

Rack Hardware & Accessories

Rack Hardware & Accessories

- 2U Blank Rack Mount Spacer, Slotted Venting

00406023

00406023 17.95 — Navepoint (Purchased: 2020/12/31)

17.95 — Navepoint (Purchased: 2020/12/31)

- Rackstuds Series II, Purple, 3.2mm, 20 pc.

B07W7BWRX3

B07W7BWRX3 17.00 — Amazon (Purchased: 2020/12/26) |

17.00 — Amazon (Purchased: 2020/12/26) |  2

2

Spray Finish

Spray Finish

- Deft Aerosol Interior Clear Wood Finish Brushing Lacquer, Satin

01713

01713 5.98 — Home Depot (Purchased: 2020/12/22) |

5.98 — Home Depot (Purchased: 2020/12/22) |  2

2

Build Pictures

Build Pictures

I attempted to document the process as best as I could. The frame was made from the 2x4s once they were transformed into 1.5x3s, the bottom mini-frame is supported by oak 2x1s that I cut from a piece of oak (1x5) in my scrap bin. I then wrapped the frame in 1/2" sanded plywood, using hardwood dowels to secure the rear frame (making it removable).

- 12U Rack Cabinet Build Pictures